We Are Shearwater Technology

At Shearwater we are passionate about using modeling and simulation (M&S) technologies to solve tough problems and develop new products. Our team has extensive experience developing and applying state-of-the-art M&S solutions to a wide range of commercial and military applications. We invite you to read further to learn more about Shearwater's unique capabilities and experience.

OUR GOAL

Our Goal at Shearwater is to provide our clients with superior engineering services in order to solve your problems quickly and effectively at great value.

OUR COMMITMENT

Our Commitment to our clients is that we will serve you to the best of our ability with integrity and honesty, and with your best interests in mind.

OUR PERSPECTIVE

At Shearwater we are always optimistic that our clients’ challenging problems can solved with hard work and determination.

Shearwater Technology Capabilities

Engineering Services and Consulting to Government and Commercial Sectors

Core Capabilities

Finite Element Analysis

Hydrocode and Hydro-structural Analysis

Engineering Model Development and Analysis

Multi-disciplinary Optimization

CAD Modeling and Mesh Generation

Software Development

Fields Of Experience

Impact, Shock, & Penetration

Material Dynamics & Failure

Response of High Explosives

Blast Effects and Target Response

Fragmentation and Debris

High Performance Computing

Shearwater employees have extensive

experience using High Performance Computing

(HPC) clusters to perform computationally

intensive analyses.

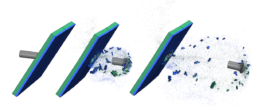

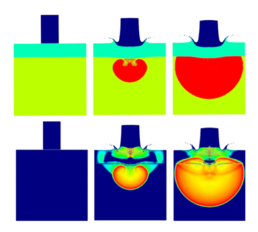

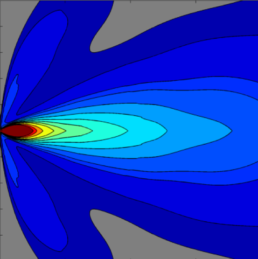

Hydrocode Analysis

At Shearwater we employ a wide range of cutting edge first-principle numerical tools to simulate highly dynamic events such as impact, shocks, penetration, blast, reactivity of energetic materials, and dynamic response and failure of materials. We have extensive experience using Lagrangian, Eulerian, and SPH (Smooth Particle Hydrodynamics) methods (including coupled methods) in conjunction with appropriate material models to accurately capture realistic phenomena and predict product performance.

Our team has the understanding to apply the appropriate numerical tool to the our client’s specific needs, enabling us to provide accurate and cost effective predictions in a timely manner. Shearwater personnel are experienced in using multiple codes, including: CTH, ALE3D, LS-DYNA, EPIC, SPHC, and others.

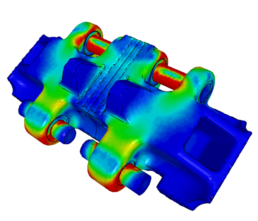

Stress Analysis

Shearwater uses LSTC LS-DYNA to perform large scale finite element analyses for rapid evaluation of mechanical stresses, strains, and deformations in component and system designs. We are skilled in using both implicit (low deformation, static and semi-static) and explicit (high deformation, high rate) numerical solvers to perform stress-strain-failure analyses.

Shearwater personnel have in-depth understanding of material behavior and apply appropriate constitutive / failure models to predict design performance. Additionally, Shearwater utilizes the Penguin-On-Demand (POD) High Performance Computing (HPC) cluster to process our computational models.

The POD provides a cost effective means to access high value computational assets, and allows for high resource availability and fast turn around times.

Engineering Model

Development and Analysis

Shearwater has a deep history developing fast-running engineering models for performing system level effectiveness evaluations. We begin the development process by leveraging high-fidelity simulations and available test data to identify key phenomena and parameters that have a first-order effect on outcomes. From this basis we develop customized analytical physics-based, empirical, and/or semi-empirical models to address the fundamentals of the problem.

Shearwater personnel have developed and implemented dozens of engineering models into parent codes for our clients. We are also skilled in using engineering models to perform broad parametric analyses to evaluate overall system performance and identify potential vulnerabilities.

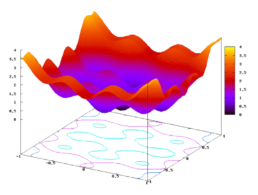

Multi-Disciplinary Optimization

Shearwater utilizes the open-source DAKOTA framework developed by Sandia National Laboratories to perform Multi-Disciplinary Optimization (MDO) analyses. DAKOTA performs automated iterative analyses using a variety of gradient based, derivative-free, and global optimizations.

The DAKOTA framework can be used in conjunction with any existing model or simulation as a black box to perform optimization, parameter studies, design of experiment (DOE) analyses, uncertainty quantification, and model calibration.

Shearwater uses DAKOTA in conjunction with our high fidelity and engineering tools to provide our clients with crucial decision-making information throughout the system and/or model development processes.